Product Description

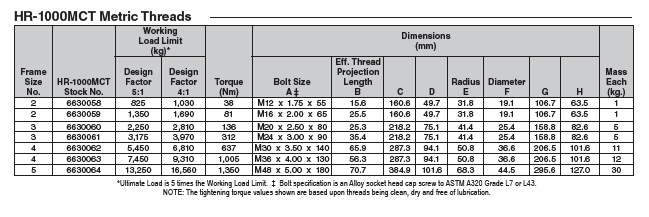

HR-1000MCT Metric Threads

• All load bearing components are heat treated, Quenched & Tempered alloy steel.

• All components, with the exception of the retaining ring, are produced with maximum material hardness of 34 HRc.

All primary load bearing components have charpy impact testing. The body, bushing, washer and bail meet impact

requirements of 31 ft-lbs min. avg. at -4°F. The bolt meets impact requirements of 20 ft-lbs min. avg. at -150°F.

• Individually Mag inspected with certification

• Forged bail provides the following:

• Easily readable raised lettering showing the name Crosby or “CG” and PIC Code for material traceability.

• Greater durability providing the increased “Toughness” desired in potentially abusive field conditions

• Larger opening than standard Hoist Ring bail.

• Top washer is color coded for easy identification (blue for UNC threads and grey for Metric threads)

• The Working Load Limit and Recommended Torque value are permanently stamped into each washer.

• Individually Proof Tested to 2 times Working Load Limit (90° and in-line).

• BOLT SIZE IDENTIFICATION: The size of the bolt will be stated as in the drawing above. Illustration shows meaning of each dimension given.

• NOTE: For Special Applications, see page 457.

• Type approval and certification in accordance with DNV O fshore Standard DNV-OS-E101, Drilling Plant, October 2013 and Standard for

Certifiation No. 2.22 Lifting Appliances.

• Frame 2 and larger are RFID EQUIPPED.

• Individually serialized.

• 100% MPI all primary load bearing components.

• Coating: Thermo-diffusion galvanized.

• Optional bolt sizes available upon request.