Product Description

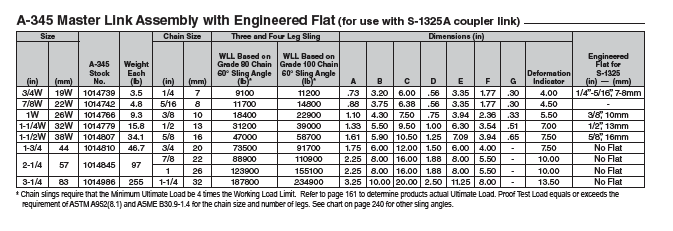

A-345 Master Link Assembly with Engineered Flat (

• Alloy Steel – Quenched and Tempered.

• Individually Proof Tested with certification. (See pages 161 for Proo

Test values.)

• Proof Tested with 60% inside width special fixtures sized to prevent

localized point loading per ASTM A-952. Reference page 276.

• Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements.

Importantly, these links meet other critical performance requirements

including fatigue life, impact properties and material traceability, not

addressed by ASME B30.26.

• Forgings have a Product Identification Code (PIC) for material traceabilit ,

along with the size, the name Crosby and USA in raised lettering.

• Selected sizes designated with “W” in the size column have enlarged

inside dimensions to allow additional room for sling hardware and

crane hook.

• Incorporates patented QUIC-CHECK® deformation indicators.